News and stories by TELAIR

27. February 2024

Innovative cargo handling systems are a key factor in the transport of goods around the world. Learn more about TELAIR’s aerospace cargo solutions!

21. February 2024

Innovative cargo handling systems are a key factor in the transport of goods around the world. Learn more about TELAIR’s aerospace cargo solutions!

19. December 2023

We look back on our accomplishments of 2023 and thank our business partners and customers.

21. December 2022

In its annual review, TELAIR looks back on the past year: from new products to first and last deliveries to successful events.

22. June 2022

The TELAIR main deck cargo handling loading system solution for the 777-300ERCF is one of the most innovative and unique cargo loading system on the market. Kansas Modification Center (KMC) and WERX at Wichita State University’s National Institute for Aviation Research (NIAR WERX) announced TELAIR International as the Cargo Loading System and Floor Panels manufacturer for the KMC 777-300ERCF passenger-to-freighter conversion of the Boeing 777-300ER air-craft.

6. October 2021

Du suchst eine Ausbildung im Landkreis Miesbach?

Dann komm auf die Stuzubi Miesbach und lerne uns kennen. Wir sind neugierig auf dich! Erfahre mehr:

12. May 2021

TELAIR received the FAA Supplemental Type Certificates for the A321-200PCF Main Deck 1.25-INCH Main Deck Cargo Loading System and Complete Main Deck Floor Panel Installation.

4. May 2021

We develop custom-made aircraft cargo loading solutions. High quality and outstanding delivery performance characterise us. Read more!

12. April 2021

Innovative cargo handling systems are a key factor in the transport of goods around the world. Learn more about TELAIR’s aerospace cargo solutions!

6. November 2020

MIESBACH, GERMANY, November 6, 2020 – TELAIR today announced that China Airlines has ordered 25 A321 Modular Cargo Loading (ModCar) Systems.

21. October 2020

6. September 2020

As of today, TELAIR International GmbH (“TELAIR”) launches a cooperation with U.S. Cargo systems (“U.S. Cargo”). As an exclusive Authorized Repair Centre U.S. Cargo will carry out repair services for TELAIR equipment in the American region in the future.

16. July 2020

Miesbach, Germany, June 16, 2020 – TELAIR today announced it has earned a spot in the Boeing Premier Bidder Program.

The program recognizes and rewards consistently high performing Boeing Commercial Airplanes suppliers and gives them an opportunity to increase their business with Boeing.

26. May 2020

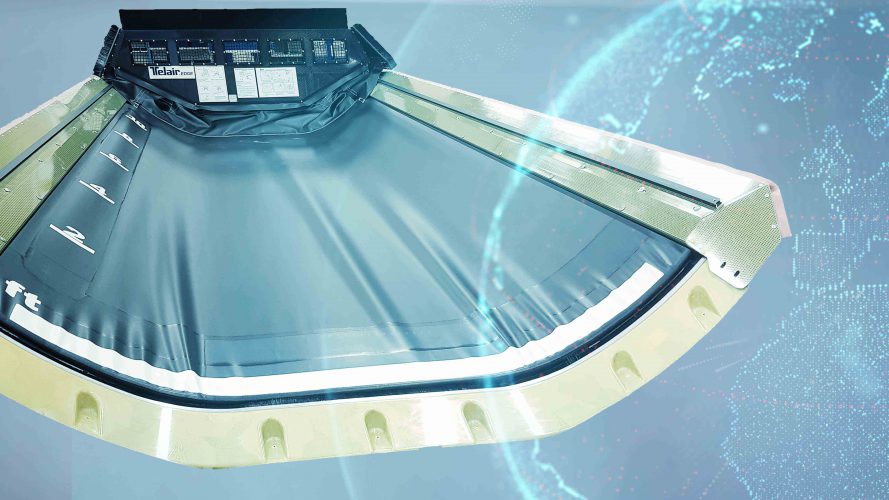

On April 30, 2020, the European Union Aviation Safety Agency, EASA, issued a Supplemental Type Certificate for the Sliding Carpet Loading System for the Embraer 190-300 (E190E2). The plan is to install the first systems in August/September this year for the airline Wideroe in Norway.

24. January 2020

TELAIR International GmbH (“TELAIR”) announced today that it has entered into a 10-year partnership agreement with HAECO Component Overhaul (Xiamen) Limited („HAECO CRO“). Telair optimizes the quality of its world-wide support by having designated HEACO as exclusive Authorized Repair Centre for the People’s Republic of China and Authorized Repair Centre in the Asia Pacific Region.

24. January 2020

Launch customer Lufthansa Group to modify more than 100 new A320/A321neo aircraft over the next 6 years beginning in 2020.

MIESBACH, GERMANY, SEPTEMBER 12, 2019 – Telair International today announced the world’s first cargo loading system, allowing the lower deck of a narrow-body aircraft to be quickly converted for different cargo requirements.

23. January 2020

321 Precision Conversions, LLC (321PC), announced Telair International as the Cargo Handling System Manufacturer for the passenger-to-freighter conversion of Airbus A321-200 aircraft.

The Telair International A321PCF main deck cargo system is the most versatile and ultra-light weight system on narrow body freighters in the industry.

23. January 2020

Miesbach – In our anniversary year of 2018, we can look back on a 50-year company history. Our company is one of the world's leading manufacturers of cargo loading and baggage handling systems in aircraft. Since our founding in 1968, we have made a decisive contribution to the development of air cargo systems, and thus to the acceleration of world trade, with our innovations and solutions, such as the so-called "tray mounted Power Drive Units."

23. January 2020

Norwegian, a leading low cost carrier in Europe, has selected the Sliding Carpet™ baggage & cargo loading system for their new B73MAX fleet. The order includes 100 firm and 100 options for the new Edge™ system, an all carbon fiber system where the weight has been reduced by an amazing 40% over prior system generations.

23. January 2020

To ease fault detection and troubleshooting of cargo systems, a remote maintenance application has been introduced and recently certified. The system is using a GSM module, built into our cargo control system, which automatically transfers information from the aircraft cargo system to a ground station as soon as ground power is applied to the aircraft.