RFID ULD tracking with remote data transmission

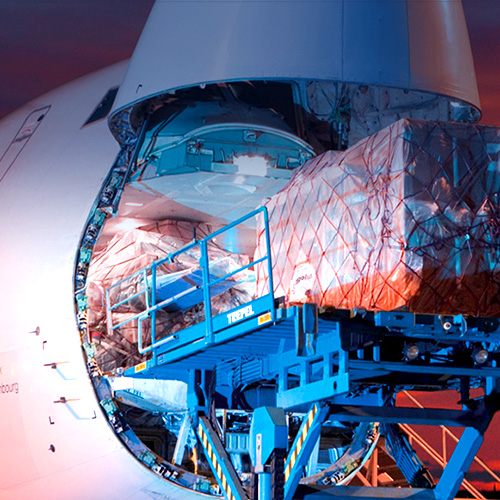

Telair has been exploring the use of passive RFID chips built within the ULD, in combination with its onboard cargo control and communication system, to introduce the ability for tracking ULD’s entering or leaving the aircraft.

This would enable the airline to automatically receive information on ULD location, ULD position within the aircraft, content of the ULD and any other relevant information.

To date, bar-code reading is the most commonly used method for tagging and identifying airline cargo and baggage. For ULDs, the aluminum pallets or containers used for stacking and holding cargo and baggage for transport in the aviation industry logistics chain, pallet, and container identification numbers are generally used. However, human interface is required to track cargo and baggage bar codes in combination with ULD numbers, resulting in errors.

Profit from TELAIR’s RFID ULD tracking technology

Further ULD tracking may be poorly managed on the platform and can lead to missing cargo, baggage and ULDs. Poor identification of ULDs per station requires an unnecessary overstock of ULDs to meet transportation demands and requires constant human monitoring, adding to the airline’s working capital. Not any more, with the Telair RFID ULD Tracking technology.

The system uses UHF antennas embedded within the Telair onboard cargo handling system components located at the aircraft entry doors. RFID chips, installed within the pallet’s edge rails, are monitored and relevant data is sent through the Telair cargo communication system to the recipient’s computer network. An integrated GPS antenna within the Telair system provides the exact location of the ULD at the time of reading.

A similar set-up can be used within cargo warehouses, at ULD docking stations, at pallet build-up areas, on ground handling equipment, etc.

Application

- All containerized aircraft models

- Pre-provisioned on following TELAIR aircraft CLS:

- B747-400F/ERF/BCF (Main Deck)

- B747-8F (Main Deck & Lower Deck)

- B747-8I (Lower Deck)

- B767-300BCF (Main Deck)

- B777F/BCF (Main Deck)

Availability

- Certification via STC process

- 9 – 12 months lead time for pre-provisioned aircraft

- 24 months lead time for other aircraft models

Design

- Passive RFID chips in ULD base plate corners

- No batteries, unlimited life

- RFID chips life time warranty

- LF antennas embedded in Telair on-board cargo system

- GSM based world-wide communication

- Integrated GPS locator

- No modification of aircraft wiring

- Operates only during ground mode

Features

- On-line monitoring of each ULD during handling

- Reduction of lost ULDs

- Avoids misrouted and / or misloaded ULDs

- Automatic ULD load plan check to avoid aircraft CG mismatch

- Quick identification and unloading of ‘no show’ passenger bags

- Improved tracking of interlining ULD’s between aircraft

- On-line control of loading & unloading process